APPLICATION

应用领域

本公司生产的JL-3280、3188水性系列含氟防水助剂,JL-6360、6361、6318油性系列含氟防水助剂,优异的性价比广泛应用在针织品涂层后处理工艺中,JL-6815、2000系列柔软抗粘助剂,亦可用于纺织、皮革领域。

本公司生产的JL-3375、3558、3390系列PU纺织品、PU处理专用手感助剂及JL-6065、6067、6069系列油性无氟防水助剂,与PU、PVC基础树脂搭配,相容性优良,产品性能优异,质量稳定,适合调制各种有特殊表面触感或三防效果需求的产品,提高附加值。

ABOUT

关于同轩

湖北同轩总部(湖北同轩高分子材料有限公司)坐落于湖北省黄冈市黄州区火车站经济开发区,是华中地区大型的功能助剂、 聚氨酯添加剂、界面活性剂、着色剂、油墨以及表面处理剂研发生产基地。总部占地面积88亩,技术设备先进,拥有一支优秀的研发生产团队。我们通过对产品、技术的坚持探索,并与各大高校进行深入的技术交流合作,同时与上海交大签订了校企合作协议,并在浙江嘉兴共同成立了研发中心,不断地研发出满足市场需求的新型产品,拥有强大的技术支撑。

NEWS

新闻动态

新闻资讯

2025-01-21

China Materials Conference 2024 and the Second World Materials Conference

On July 9, 2024, the China Materials Conference 2024 and the Second World Materials Conference, hosted by the Chinese Materials Research Society, co-hosted by the European Materials Research Society, and organized by Guangdong University of Technology, grandly opened at the Guangzhou Baiyun International Conference Center. This conference is an academic exchange event in the field of new materials, interdisciplinary, cross-field, and cross-industry, held against the backdrop of accelerating the advancement of high-level technological self-reliance and strength. It is a new brand conference in the Chinese new materials community, characterized by high academic standards, a wide range of fields, and cutting-edge dynamics. Nearly a hundred academicians and over 25,000 materials science and technology workers attended the conference.

新闻资讯

2025-01-21

The Key Laboratory of Functional Polymer Materials of the Ministry of Education held an academic committee meeting.

Nankai News Network (Correspondent Li Zhanyong) - On March 17, the 2023 Annual Academic Committee Meeting of the Key Laboratory of Functional Polymer Materials of the Ministry of Education (hereinafter referred to as "Key Laboratory") was held at Nankai University. The meeting was chaired by Academician Yang Yuliang, the director of the Academic Committee of the Key Laboratory, and Academician Yang Wantai, the deputy director.

The China Resources Environmental Group Technology Innovation Conference was held: Strengthening innovation empowerment and stimulating innovation vitality.

The China Resource Recycling Group Co., Ltd. (hereinafter referred to as "China Resource Recycling Group") held a technology innovation conference in Tianjin. The conference aims to summarize the insights and achievements in "technology innovation" since the establishment of China Resource Recycling Group three months ago, and to discuss and exchange ideas on the innovative development path of the resource recycling industry with industry experts. It seeks to promote the high-end, intelligent, and green development of the industry, accelerate the creation of a national, functional resource recycling and reuse platform, better ensure national resource security, and contribute to the construction of a beautiful China.

2024 Polymer Materials Recycling Conference: Leading Future Trends in Green Transformation and Industrial Innovation

Against the backdrop of increasing global attention to sustainable development and the green economy, the recycling and utilization of polymer materials is not only an important means to address environmental pollution but also a key lever for promoting the transformation and upgrading of the chemical industry. Recently, the highly anticipated 2024 Polymer Materials Recycling Conference will be held in Ningbo, China, from December 20 to 21. Many heavyweight companies in the industry, such as Sinopec, PetroChina, Wanhua Chemical, and Kingfa Technology, will gather to discuss cutting-edge technologies and future trends in this sector.

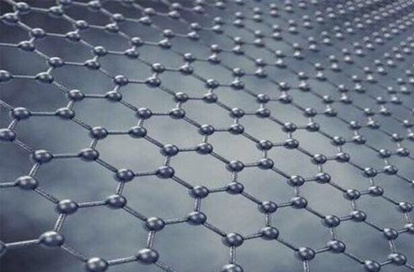

The polymer materials industry is developing towards high performance, multifunctionality, and intelligence.

Polymer materials are important raw materials for plastic products, and downstream customers have high requirements for quality consistency, environmental indicators, and supply stability. Once suppliers are locked in, they will not be changed without significant quality or price changes, as this would affect production continuity and quality consistency, and increase costs. Therefore, polystyrene companies have stable cooperation with downstream customers, benefiting from first-mover and brand advantages, which create barriers between customers and brands. At the same time, chemical raw materials are bulk commodities with sales and procurement radii, making it difficult for new entrants to choose locations, thus forming locational barriers.